TECHNOLOGY

MECHANICAL DRIVE

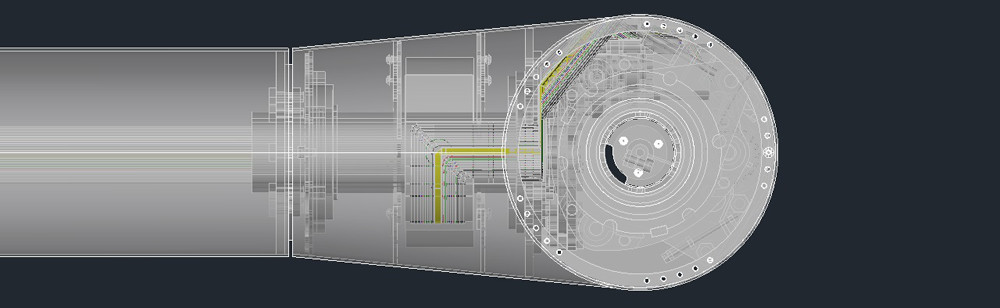

Our two axis drive mechanism is composed of three-stage friction drives powered by a stepper motors. Due to high grade steel alloys and ball bearings used in all moving connections tracking mechanisms can reach extreme longevity. Mechanisms shown no wear after tests extending 20.000 main shaft cycles (which corresponds to over 50 year's operation as heliostat).

Metal-metal type friction drives are used in high end astronomical telescopes and some types of car transmissions. No mechanical backlash, and very smooth operation are they most distinctive characteristics. Among that is also natural resilience to overloads. When external obstacle or impact is introduced, drive will simply slip out of desired position.

Only drawback of all friction drives is lack of synchronization between pulleys, which in a normal circumstances can lead to accumulation of positioning inaccuracies over time.

For that reason each of our drives is supplemented with high resolution angular encoder. Each encoder increment (every 0.045degree) is compared with motor micro steps value, and in case of any misalignments necessary corrections are made.

That kind of hybrid solution gives both advantages of friction drives, and encoder controlled servo drives resulting accuracy of one stepper motor micro step travel angle (0.003degree)

CONSTRUCTION

Putting artist's dream into real world isn't always an easy task.

Synergy between beauty and technical perfection can be achieved only thru meticulous fine tuning process. It is similar to evolution in natural world - good, working solutions are passed into next version, some new features are added, end result are tested, and cycle is repeated until there is no possible improvement left to be made.

That is the way our product was created and refined.

Main body is based on 2mm thick steel external shell which is both a rigid structural support and weather tied confinement for mechanical and electronical components.

Important benefit of such construction is extreme rigidity and wind resistance. FEA and CFD computer analysis used in design process suggesting that in worst case scenario (mirrors facing wind perpendicularly) construction is able to withstand 110km/h air flow. With automatic wind protection (switched on by default) mirrors will set parallel to the ground giving very small effective surface area and resistance to winds reaching 350km/h.

ELECTRONIC MODULE

Electronic module is based on latest programmable microcontroller (cortex M3), which manages all internal components (RTC timer, GPS module, Stepper motor drivers, optical encoders, and radio control module) Whole device is designed in respect to maximal power saving. Components which aren't temporary in use (e.g. GPS module) are turned off. During night, system goes complete shutdown consuming only 0.1W.

Efficient voltage regulators are accepting 9V to 36V input voltage, enabling usage of variety of power scores, including solar panels.

By using passive PoE (Power over Ethernet) connector whole system can be powered by standard off the shelf Ethernet cable.

SOFTWARE

Our system is taking advantage of a fact, that precise sun position is predictable centuries ahead.

Through advanced celestial algorithms, and mirror reflection equations optimal mirror position is determined on each following second.

This working principle is widely used in most demanding industrial applications. Main reason for that is very high accuracy, unachievable with simpler, photosensor based methods.

For convenience we added a GPS module which acquire accurate location and time automatically on each sunrise. System can also work without GSP signal, by setting time and location manually.

All functions and options are composed in easy to use and intuitive manner. User settings like programmed targets or active operation mode are stored in non-voitale memory.

Pc software provided with heliostat enables more advanced usage and configuration:

- changing speed and acceleration profiles,

- programming additional remote controllers,

- GPS diagnosis,

- input voltage readout,

- changing elevation axis position during night (parallel / perpendicular to the ground)

- enabling, and disabling: power saving mode; wind protection mode; buzzer

- enabling and disabling mirror offset correction (useful for high precision heliostat applications)

- directly moving both axis by cursors or by designating angles with 0.003degree resolution.

Both electronic module and pc interface software are fully upgradable.

| mirror surface area | 2,3m² |

| sun reflection peak power | 2,2kW |

| light beam maximum focus | x10 |

| positioning accuracy | 0,003° |

| reflection accuracy over distance: 10m / 100m | 0,5mm / 5mm |

| max angular speed | 30°/sec (5rpm) |

| X axis (azimuth) range | 540° |

| Y axis (elevation) range | 105° |

| torque | 40 Nm (4 kg/m) |

| maximum shaft load | 150 kg |

| power comsumption day / night / avarge | 2,8W / 0,1W / 1,4W |

| maximum power consumption (two axis moving at maximum speed) | 25W |

| power adapter | 12V |

| imput voltage range | 9V - 35V |

| operating temperature range | -40°C + 70°C |

| maximum wind speed (perpendicular / parallel to mirrors) | 110km/h / 360km/h |

| max height / max with | 2m / 2,45m |

| height to the main shaft | 1,2m |

| total weight | 110 kg |

contact@novasolarsystems.com